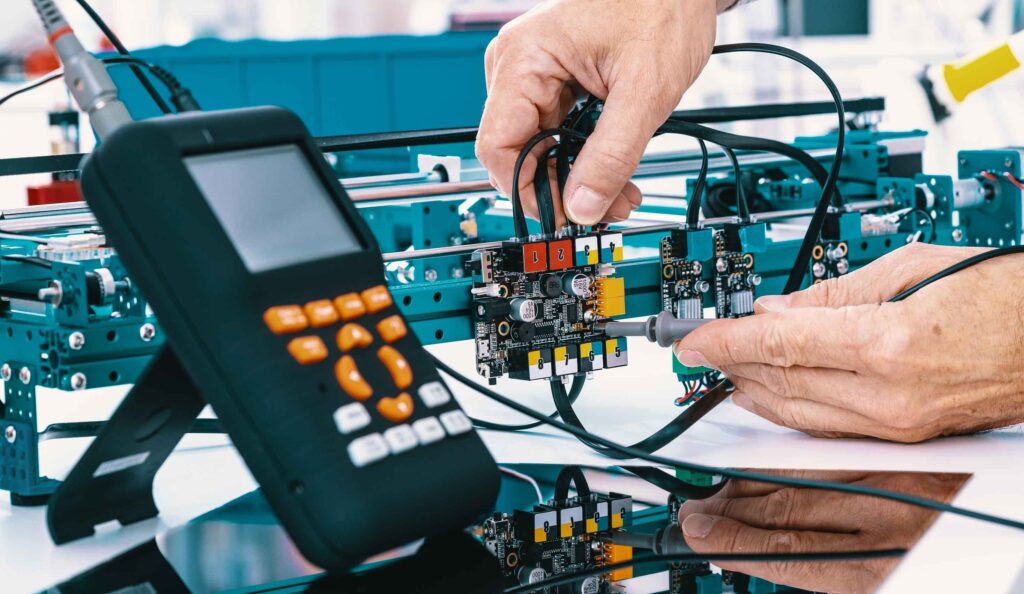

IMC Technicians

These skilled professionals are the backbone of successful IMC systems. Their responsibilities include:

- Installation and commissioning: Setting up and calibrating sensors, controllers, and other equipment.

- Maintenance and troubleshooting: Ensuring proper operation of the system through regular maintenance and repair of equipment.

- Data analysis and interpretation: Monitoring and analyzing process data to identify trends and potential issues.

- Reporting and documentation: Maintaining accurate records of system performance and activities.